Carnot has been awarded £2.3M to develop a zero-emission 50kW Hydrogen auxiliary engine demonstrator in conjunction with our partners Carisbrooke Shipping, Brunel University and the Manufacturing Technology Centre.

Following design and simulations, the hydrogen-fired engine will be bench tested in one of Brunel University’s world-leading, hydrogen-approved test cells before being integrated into a containerised system and mounted on the deck of one of Carisbrooke Shipping’s K-Class cargo vessels for a 40-day sea trial in early 2025.

Bureau Veritas and The Maritime and Coastguard Agency are also being engaged as the vessel’s regulatory authorities to ensure the fastest path to regulatory compliance. This will be among the first projects to achieve Approval in Principle for a Hydrogen power generation technology on board a UK Flagged vessel.

Decarbonising the Maritime sector

The global shipping industry faces an enormous decarbonising challenge, currently accounting for 3% of global Greenhouse gas emissions. Existing IMO regulations stipulate that by 2030, all vessels must reduce their CO2e per ton-mile 40% compared to 2008 levels, and by 2050 must be completely Net Zero.

Most cargo vessels are built with a 20+ year lifespan in mind which puts operators in a huge dilemma – existing vessels will not comply with 2030 regulations thus shortening their operational lifetime considerably and likely to loose money but new vessels cannot be ordered as technologies do not currently exist which can effectively and economically decarbonise their operations.

Some smaller vessels running shorter ranges will be able to consider electrification or fuel cells but for long-distance, ocean-going cargo vessels this is not viable. The costs, weights and practicalities become prohibitive and it is this bracket where engines offer a compelling solution, if they can operate in an economical and Zero emission manner.

This is where our technology comes in!

What is the project?

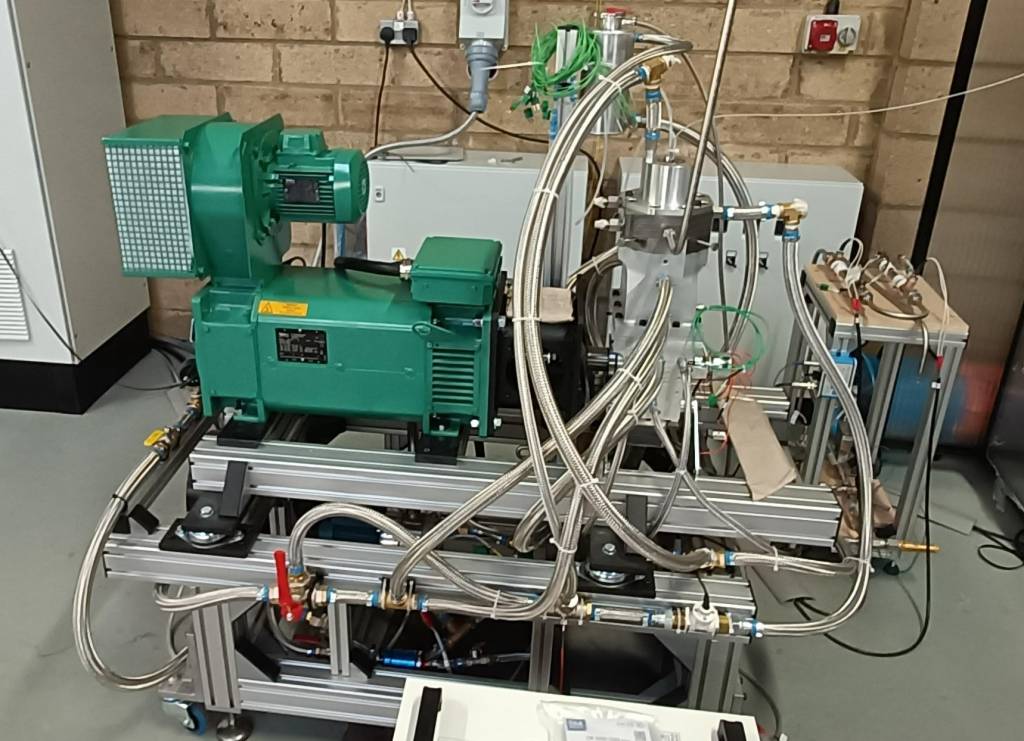

With our partners, we are developing a containerised and productised version of our 50kW engine operating on Hydrogen as an Auxiliary Power Unit demonstrator, to prove that our technology can be operated safely in the Maritime environment. This will be a valuable asset and precursor to planned 200-400 kW APUs and 1-10 MW main engines.

The APU will have at its heart, our revolutionary hydrogen combustion engine. By pioneering the use of technical ceramics in combustion engines, we have eliminated the major limiting factor to engine efficiency. Our engines have a break thermal efficiency of 70%, nearly double what is achieved by modern state-of-the-art engines which massively reduces fuel consumption and thus, reduces fuel costs. To deliver the same power output, our fuel consumption would be reduced by 45%.

Above a certain air-to-fuel ratio, hydrogen combustion emits zero emissions, i.e. negligible CO2, NOx and PM. Combined with world-beating efficiency, we believe Carnot engines will be the future propulsion and auxiliary power technology of choice within the Maritime industry.

The APU will go onboard a Carisbrooke Shipping K-Class vessel and underdo a 40-day sea trial through the Northern European, Baltic and Mediterranean seas. This will bring the technology up to TRL 6 and help validate the emission savings that we predicted during our CMDC 1 Grant project, namely targeting annual emission savings of:

- 1,740 tons of CO2e

- 357 CO2e tons of SO2

- 470t CO2e tons of PM2

- 178 CO2e tons of NOx

We will be working closely with our Classification Society partners Bureau Veritas, the Maritime Coastguard Agency, Insurance underwriters, charterers and Port authorities throughout the process to deliver the project safely and within the regulatory framework.

Who are the partners?

Our project partners for this include Carisbrooke Shipping, a family-owned business with over 50 years in business and has a long-standing commitment to innovation. The company’s philosophy is to lead the industry by building new, more efficient vessels to replace the existing ones and around 100 vessels were built at shipyards all over the world. Their previous project featured optimised bow design improving fuel efficiency by 20% compared to the existing similar ships on the market at that time.

We are then working with the Manufacturing Technology Centre (The MTC), a world leading organisation which focused on manufacturing expertise. They are bringing a wide range of skillsets including industrialising, manufacturing at scale and manufacturing for cost. They will help refine the design and supply chain to accelerate commercialisation and quantifying embedded CO2 emissions in the production process.

Brunel University are one of the leading research institutions in the UK on hydrogen combustion and they will bring expertise including test facilities, combustion simulation and design optimisation expertise.

Interested in finding out more?

If you would be interested in finding out more about this technology, deploying a hydrogen field trial or using these engines in your operations, please get in touch and fill out the form below:

The Carnot High Efficiency Hydrogen Combustion Engine Demonstrator project is part of the Clean Maritime Demonstration Competition Round 3 (CMDC3), which was announced in September 2022, funded by the Department for Transport and delivered in partnership with Innovate UK. As part of the CMDC3, the Department allocated £60m to 19 flagship projects supported by 92 UK organisations to deliver real world demonstration R&D projects in clean maritime solutions. Projects will take place in multiple locations around the UK from as far north as the Shetland Isles and as far south as Cornwall.

The CMDC3 is part of the UK Shipping Office for Reducing Emission’s (UK SHORE) flagship multi-year CMDC programme. In March 2022, the Department announced the biggest government investment ever in our UK commercial maritime sector, allocating £206m to UK SHORE, a new division within the Department for Transport focused on decarbonising the maritime sector. UK SHORE is delivering a suite of interventions throughout 2022-2025 aimed at accelerating the design, manufacture and operation of UK-made clean maritime technologies and unlocking an industry-led transition to Net Zero.