Skip to content

Skip to sidebar

Skip to footer

This grant, part of the Clean Maritime Demonstration Competition delivered by Innovate UK, will develop a novel liquid Ammonia engine concept, delivering unrivalled efficiency whilst eliminating emissions from maritime power. We will be targeting heavy-duty maritime power applications, including Main Engines, onboard Auxiliary Power Units (APUs) and Shoreside Power for cold ironing.

At the heart of the system is Carnot’s high temperature engine technology capable of achieving 70% break thermal efficiency, twice what can be achieved with modern state of the art engines. By doubling the efficiency, fuel consumption is halved thus providing considerable cost savings for operators and providing valuable economic incentives to decarbonise.

Utilising liquid Ammonia fuel offers the benefits of decarbonised fuel and high energy density but without the challenges and energy losses associated with cryogenic hydrogen storage. Ammonia is however a more challenging fuel to use in a combustion context, due to its lower reactivity and slower combustion speeds. Conventional engines solve this issue by blending ammonia with fossil fuels, thus persisting with harmful emissions.

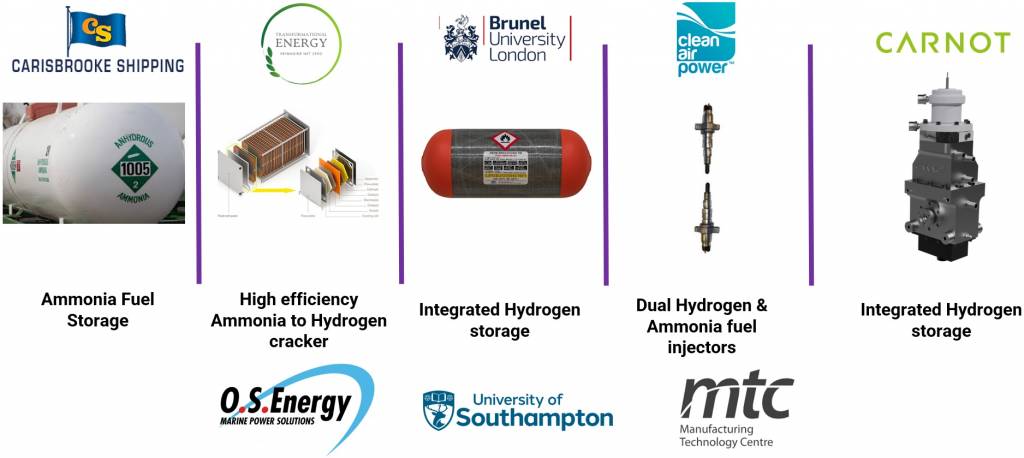

Carnot Engines utilise a hydrogen & ammonia fuel blend, utilising Ammonia Cracker technology from Transformational Energy, continuously converting ammonia into hydrogen to improve performance and deliver a decarbonised dual fuel engine.

The University of Southampton are employing comprehensive physics-based 3D-Computational Fluid Dynamics modelling to simulate mixing, ignition and combustion characteristics which will then be validated at Brunel University London, utilising their state-of-the-art optical chamber.

Throughout the project, our industry partners Carisbrooke Shipping and OS Energy, will provide operational data, integration insight and analysis to understand the implementation and benefits of ammonia fuel technology can provide to a vessel operator.

The project will conclude with a bench demonstrator to validate the feasibility of a high-efficiency ammonia engine for heavy-duty marine power.

This project is part of the Clean Maritime Demonstration Competition Round 4 (CMDC4), funded by the UK Department for Transport (DfT) and delivered by Innovate UK. CMDC4 is part of the Department’s UK Shipping Office for Reducing Emissions (UK SHORE) programme, a £206m initiative focused on developing the technology necessary to decarbonise the UK domestic maritime sector.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |